After reading this essay you will learn about: 1. Meaning of Solid Waste 2. Classification of Solid Wastes 3. Causes of Solid Waste Pollution 4. Collection 5. Effects 6. Management 7. Municipal Solid Waste Treatment 8. Industrial Solid Waste Treatment 9. Disposal.

Essay Contents:

- Essay on the Meaning of Solid Waste

- Essay on the Classification of Solid Wastes

- Essay on the Causes of Solid Waste Pollution

- Essay on the Collection of Solid Wastes

- Essay on the Effects of Solid Wastes

- Essay on the Management of Solid Wastes

- Essay on the Municipal Solid Waste Treatment

- Essay on the Industrial Solid Waste Treatment

- Essay on the Disposal of Solid Wastes

ADVERTISEMENTS:

ADVERTISEMENTS:

Essay # 1. Meaning of Solid Waste:

Any unwanted or discarded material from residential, commercial, industrial, mining and agricultural activities that causes environmental problems may be termed as solid waste. Solid waste management comprises of systematic control of the generation, storage, collection, separation, treatment, processing, recycling, recovery and disposal of solid wastes.

Solid waste encompasses the highly heterogeneous mass discarded materials or throwaway from the urban community as well as the more homogenous accumulation of wastes generated by agriculture and industrial activities.

Essay # 2. Classification of Solid Wastes:

Solid wastes can be classified into the following categories:

i. Garbage or Food-Wastes :

ADVERTISEMENTS:

These are meat, fruit or vegetable residues which decompose rapidly (putrescible) especially in warm weather.

Examples:

Vegetable and fruit peels, leftovers, meat, bones, spoiled food items.

ii. Rubbish:

ADVERTISEMENTS:

These do not decompose rapidly.

These are further of two types:

(a) Combustible:

Examples:

ADVERTISEMENTS:

Paper, Cardboard, Textiles, Wood items, Rubber, Leather, Plastic container.

(b) Non-Combustible:

Examples:

Crockery, metals, aluminium cans, tin cans etc. empty glasses and bottles.

iii. Agricultural Wastes:

These include crop residues from agricultural fields, farm manure etc.

Examples:

Jute, cotton, rubber, tea, coffee, coconut, sugarcane wastes, Rice straw, Cattle-shed wastes.

iv. Industrial Wastes:

These arise from industrial activities.

Examples:

Fly-ash, sewage, chemicals, sludge, paints, toxic metals etc.

v. Hazardous Wastes:

Those wastes which adversely affect human, plant or animal life.

Examples:

Radioactive wastes, toxic chemicals. Flammable wastes, explosives, hazardous biological wastes from hospitals or research institutions.

vi. Pathological Wastes:

Examples:

Carcass of animals slaughter house wastes (blood, pieces of meat, hair, fat, bone chippings, hides, skin excretions etc.

vii. Demolition and Construction Wastes:

Demolition, construction and repair of residential, commercial and industrial buildings generate plenty of solid wastes.

Examples:

Stones, bricks, concrete, dust, plaster, electrical, plumbing and sanitary parts.

viii. Aquatic Weeds:

These are a menace because of their prolific growth. They increase water borne diseases, hinder traffic and fishing and cause eutrophication.

ix. Miscellaneous Wastes:

Wastes not included in any of the above categories.

Examples:

Street sweepings, Roadside litter, dead stray animals, abandoned vehicles etc.

x. Domestic wastes:

Municipal wastes.

xi. Municipal Solid Wastes (MSW):

MSW include garbage and rubbish from households, hotels, offices, markets etc. Garbage denotes biodegradable food wastes while rubbish is used for non-biodegradable wastes which may be combustible (e.g., paper, plastic, tyres) or non-combustible (e.g., glass, metals, used containers etc.)

xii. Industrial Solid Wastes: These wastes are:

(a) Process wastes which depend upon the type of the products being manufactured such as tannery wastes, food processing wastes, plastic and rubber waste etc.

(b) Non-process wastes like packing waste, cafeteria wastes are common to all industries.

(c) Biomedical Solid Wastes. BMW include pathological and surgical wastes.

(d) Agricultural Wastes. These wastes result from farms, feed lots and livestock yards. Horticulture wastes consist of vegetable parts.

xiii. Other Wastes:

Construction/demolition wastes include debris, rubbles, wood, concrete etc.

a. Radioactive hazardous wastes are from nuclear power plants and laboratories etc.

b. Electronic wastes originate from discarded electronic devices such as TV computers.

The annual solid waste production in India is: Domestic and trade (8.5%), industries (15.2%), thermal power stations (7.3%), mining (67%) and construction (2%).

Essay # 3. Causes of Solid Waste Pollution:

The reasons for the rapid growth in the quantity of solid wastes are over population, affluence and technology.

A. Over-population:

As the number of people producing a pollutant increases, pollution will naturally increase. Same is true for solid waste pollution also which increases with the increase in population.

B. Affluence:

(i.e. production or per capita consumption) With affluence there is a tendency to declare items a being in or out of fashion and promptly throw away the ones out of fashion. This results in solid waste pollution.

C. Technology:

(i.e. amount of production produced per unit of economic good.) Rapidly growing technologies for most economic goods indicator a shift in technology from the returnable packaging to non-returnable packaging. This has resulted in the phenomenal growth of packaging industry which encourages self-service merchandising by packages that help top sell the product by themselves.

Returnable glass containers or bottles are being replaced by non-returnable cans, bottles, paper boards and plastic containers. Packaging is largely responsible for causing solid waste pollution because packaging materials like plastic bags and cans etc. are not biodegradable and persist unchanged in disposal operations such as landfills. Plastic can be recycled to make new packs but recycled plastic soon loses its strength, becomes brittle and is easily broken up by wind and rain.

(i) Composition,

(ii) Density and

(iii) Energy content.

Essay # 4. Collection of Solid Wastes:

Collection includes all the activities associated with the gathering of solid wastes and hauling of the wastes collected to the location from where the collection vehicle will ultimately transport it to the side of disposal.

There are three basic methods of collection:

(a) Community Storage Point:

The municipal refuse is taken to fixed storage bins and stored till the waste collection agency collects it daily for disposal in a vehicle.

(b) Kerbside Collection:

In advance of the collection time, the refuse is brought in containers and placed on the footway from where it is collected by the waste collection agency.

(c) Block Collection:

Individuals bring the waste in containers and hand it over to the collection staff who empties it into the waiting vehicle and returns the container to the individuals.

Essay # 5. Effects of Solid Wastes:

Municipal solid wastes heap up on the roads due to improper disposal system. Open dumping allows biodegradable materials to decompose under unhygienic conditions. This produces foul odour and breeds disease vectors and infectious pathogens besides spoiling the aesthetics of the site.

i. Industrial solid wastes are the source of toxic metals and hazarduous wastes which may leach or percolate to contaminate the ground water.

ii. The hazardous wastes are mixed with garbage and other combustible waste. This makes segregation and disposal more difficult and risky. Various types of wastes like cans, pesticides, solvents, radio-isotopes, plastics, etc. are mixed with paper, scraps and non-toxic materials which could be recycled.

Burning of these wastes produces furans, dioxins, poly chlorinated biphenyls which have the potential to cause several ailments including cancer.

Essay # 6. Management of Solid Wastes:

The aim of waste management is to collect, treat, utilize, control and dispose solid wastes in an economic manner consistent with the protection of public health. Its major consideration apart from health is to adopt three R’s-reduce, reuse and recycle strategy.

(i) Reduction in use of raw materials:

This will correspondingly decrease the production of waste. Reduced demand of any metallic product will decrease the mining of their metal and cause less production and less waste.

(ii) Reuse of waste materials:

Reuse of paper, cardboard, glass, metal, plastic, discarded cycle tubes, auto-parts of vehicles considerably reduces the waste of generation.

(iii) Recycling of materials:

Recycling is the reprocessing of discarded materials into new useful products. Examples include formation of new cans, bottles from broken aluminium cans and glass, fuel pellets from kitchen waste, cellulose from waste paper, ethanol from bagasse etc. Coal ash, the residue left after coal combustion for power generation, is an important source of ferrosilicon, silicon and aluminium.

One tonne of solid waste processed by pyrolysis is believed to yield an energy equivalent to one barrel of oil. One tonne of combustible waste produces energy equal to 9 million BTU of heat or 65 gallon of fuel oil or 9000 cubic feet of natural gas.

It involves following steps:

a. Collection of municipal wastes.

b. Applying scientific methods for the disposal of solid wastes.

c. Sorting of waste materials.

d. Dumping of non-combustible and harmless substances into dump sites.

e. Compositing organic substances which are biologically degradable. According to an estimate a town with one lakh population may generate 20,000 tonnes of garbage and 8000 tonnes of night soils which can be converted into 18,000 tonnes of compost manure.

f. Burning of combustible substances in specially designed incinerators such as Multiple Hearth Furnaces (MHF) and Furnaces (FBF). Pyrolysis is the best way to treat solid wastes.

g. Now National Environmental Engineering Research Institute (NEERI) Nagpur had under-taken comprehensive surveys of metropolitan cities to make the best use of waste.

Essay # 7. Municipal Solid Waste Treatment:

Composition of MSW:

The average composition of MSW is: 30 to 40% organic matter, 30 to 40% fine materials, 5% paper, 1% glass, 1% metals and 1% plastic. Actual composition of MSW varies demographically.

For disposal of wastes, following treatment methods are adopted.

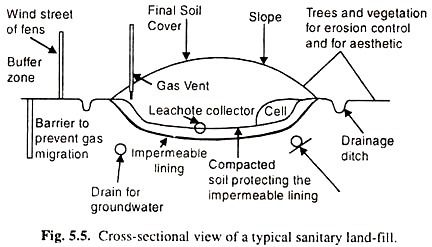

i. Sanitary Landfill:

In sanitary landfill operation, garbage is spread in thin layers compacted and covered with clay or plastic foam. In the modern landfills, the bottom is covered with an impermeable liner, usually several layers of clay, thick plastic and sand. The liner protects the ground water from being contaminated due to percolation of leachate.

Leachate from bottom is pumped and sent for treatment. When landfill is full it is covered with clay, sand, gravel and top soil to prevent seepage of water. Methane produced by anaerobic decomposition is collected and burnt to produce electricity or heat.

Other methods of landfil treatment are sewage farming, spray irrigation, ridge and furrow and lagooning etc. In India, there exist 200 sewage farms covering 25000 hectare of land and using 650 million gallons of sewage per day.

With increase in urbanisation, planned sanitary landfill, backed by modern solid waste management, can provide the community with better environmental management.

ii. Composting and Municipal Waste Composting Projects:

Composting is the aerobic and thermophilic decomposition of organic waste to humus by micro-organisms like bacteria, fungi and worms. The process is conducted by a complete automatic system, (i) The crude refuse is dumped into a container or to a belt conveyor, (ii) Iron or metallic particles are removed by a magnetic separator.

The wet material is then transferred to a rotatory cylinder which rotates on large tyres. Here aerobic microbes rapidly decompose pulverized wastes under aerobic conditions. The Government encourages feeding of compost plants by municipal wastes. Compost has been used by Indian Agricultural Research Institute to produce blue-green algae coated granulated compost.

iii. Vermi Composting:

In vermiculture, earthworms feed on and degrade a variety of organic waste, eliminate noxious elements and convert the waste into high grade nutrient rich vermi-compost. It is very useful biofertilizer and soil conditioner.

iv. Incineration:

Incineration involves burning of solid wastes at high temperature either on batch or continuous type incinerators. The modern municipal incinerators are of continuously burning type. These are equipped with large storage bins, automatic feed hoppers, moving grates, ash discharging systems, pollution control devices like scrubbers and electrostatic precipitators. The unit yields stable residue free from offensive odours. The waste heat of combustion can be utilized for supplementing electricity generation for domestic heating etc. However, the technique involves expensive equipment.

Essay # 8. Industrial Solid Waste Treatment:

i. High Temperature Incineration of Industrial Solid Waste:

It is a recent innovation where high temperature (–1650°C) is attained using supplementary fuels. The non-combustible fractions of the refuse (metals, glass) can be melted and reused.

Flash type incinerator, multiple hearth, rotary and fluidized bed type incinerators are finding wide applications in industrial waste disposal. If incineration becomes an economical method for solid waste disposal, useful material and energy shall be recovered by the process.

Heat can be recovered by putting a waste heat to boiler or some other recovery device on an existing solid waste incinerator. The heat so recovered can be utilized for generating electricity or for space heating purposes. The solid waste has about one-third the heating value of coal, but unlike coal it has a very low sulphur content.

Advantages of Incineration:

a. Volume of the waste is reduced to more manageable levels thereby reducing the transportation costs upto the ultimate disposal site.

b. Incineration reduces the land requirement to one third of that required if the refuse is to be land filled.

c. The residue after incineration is free from any degradable materials. Moreover, the stabilised residue eliminates the need to transport the recovered material to the land fill site.

Disadvantages of Incineration:

a. Incineration leads to air pollution unless the plant is designed, equipped and operated to comply with air pollution standards.

b. Typical air pollutants from incineration are SO2, flyash, HCl and organic acids.

c. Operation cost is high. Ordinary incinerators cannot be used for radioactive wastes.

ii. Pyrolysis:

The chemical energy of some organic wastes can be recovered by destructive distillation or pyrolysis of the solid waste. The combustible constituents of the solid wastes are heated in a special retort, i.e., pyrolysis reactor at about 1000°C in a low-oxygen or an oxygen free environment. This is an endothermic process and it differs from the conventional incineration.

Pyrolysis of the solid waste yields the following components:

(i) Tar or oil phase containing acetone, acetic acid and methanol etc.

(ii) Gaseous phase containing H2, CH4, CO, CO2 etc.

(iii) Solid phase containing pure carbon, char and inert materials like glass, rocks, metals.

Advantages of pyrolysis include:

(i) Volume reduction by about 90%.

(ii) Possibility of handling potentially hazardous plastics, e. g., PVC in a safer way.

iii. Vitrification:

The recent technique insitu vitrification aims at converting the solid wastes into a sort of glass. To accomplish this method electrodes are inserted into the waste heap and a very powerful electric current is passed through it. The strong heat so produced melts glass, plastic, muck, mud and other wastes into glass like solid. It can be dumped anywhere as it leaches very little. However, in this method care is taken to prevent mingling of radio wastes with other organic compounds.

Essay # 9. Disposal of Solid Wastes:

Before the solid waste is ultimately disposed-off, it is processed in order to improve the efficiency of solid waste disposal system and to recover usable resources out of the solid wastes.

Before disposal – Collection of municipal solid wastes and industrial solid waste collection. Transportation, transfer station, storage discharge state.

Due to heterogeneity of the city refuse it is important to select the most appropriate solid waste disposal method keeping in view the following objectives:

(a) It should be economically viable i.e., the operation and maintenance costs must be carefully assessed.

(b) It should not create a health hazard.

(c) It should not cause adverse environmental effects.

(d) It should not be aesthetically unpleasant i.e. it should not result in offending sights, odours, and noises.

(e) It should preferably provide opportunities for recycling of materials.

Following should be known:

(i) Quality of waste physical, chemical characteristics.

(ii) Identification of recoverable materials.

The methods of disposal commonly used are:

Salvage or Manual Separation:

Separation of metals and glass is necessary because their compactor use is not possible.

For this we can use magnetic separator and utilize properties of some materials to magnetised in presence of a magnet.

Aside from magnetic separator there are number of density and specific gravity separation devices.

The use of vibrating screen at by use of frequency of screen oscillations separates materials of different specific gravity. Centrifugal can be used or employed to move a heavier material from a lighter material.

It is worthwhile for resources recovery.

Before ultimate disposal, the manual separation of solid waste components is accomplished to achieve the recovery and reuse of materials. Cardboard, newsprint, high quality paper, glasses, metals, wood and aluminium cans etc. are manually sorted out or salvaged either for recycling or for resale.

Compaction or Mechanical Volume Reduction:

After separation or reusable or disposable articles, compactors are used to compress the waste materials directly into large containers or to form bales that can be then placed in large containers. Compaction increases the useful life of landfills. A compactor generally will reduce waste volume by a factor of from 3 to 1 to 10 to 1, depending upon the material to be compacted and the force required to compact it.

Compactors generally consist of a container unit and a compaction unit. The container unit accepts the raw trash and feeds it into the compactor. The compactor consists of a hydraulically or pneumatically operated ram, which squeezes the waste into more dense form by utilizing high pressure. Compactor should not accept, sludge, heavy pieces of wood, metal, glass and heavy plastic.

Stationary Compactor:

Stationary compactors where compactor unit having hydraulically operated ram which moves in a horizontal direction. Waste are fed into a receiving hopper and ram. Which can be actuated either manually or by optical or sonic devices, then compresses the waste into a steel container, is generally square or rectangular and has opening in the lower half of one end of the box.

This opening allows the compactor ram to operate inside the container during the completely full, the compaction cycle. When a container is completely full, the compactor ram is entirely withdrawn. The container is lifted on to a tilt frame hoist type truck to be hauled away and a new empty container is then strapped or locked to the compactor making the unit once again ready for operation. Pivoting ram compactor used for smaller lighter materials.

Consideration while using compactors arc usually cycle time, pressure on ram face. Rotary type compactors consists of a ram mechanism for loose waste and a platform rotates which indexes the position again and again.

Incineration or Thermal Volume Reduction:

If solid waste will burn it can be incinerated. Highly combustible wastes like plastics, cardboard, paper, rubber and combustible wastes like cartons, wood scrap, floor sweepings, food wastes etc. are subjected to incineration i.e. burning at very high temperatures.

Incineration results in air pollution and so proper control equipment need to be installed to avoid contamination of environment.

In order to make this method economical, the heat generated during incineration is usefully utilised by generating steam or by putting a waste heat boiler on the incinerator there by partly recovering the cost of waste collection and disposal.

(i) The charging should be thorough and rapid.

(ii) Each batch of refuse entering the furnace should be well mixed.

(iii) The proportion of the fuel in the charge be adjusted to provide complete combustion.

(iv) The temperature in combustion chamber should be 670°C.

Advantages of Incineration/Thermal Volume Reduction:

(i) Most sanitary method.

(ii) No odour trouble.

(iii) No dust nuisance.

(iv) Steam power and clinker can be sold.

(v) Requires less space.

Limitations of Incineration:

(i) Solid waste should have high calorific value.

(ii) Smoke and ash nuisance.

Waste bunker→ Rotary kiln→ Afterburner→ Waste heat boiler→ Electrostatic Precipitator → Quencher → Scrubber – Reaction tube → Prag filter → Stack.

Hazardous waste incineration plant.

Open Dumping:

Open dumping of solid wastes is done in low lying areas and outskirts of the towns and cities. Being comparatively cheaper, this method of disposal is used extensively in India.

However, major disadvantages are:

(a) Public health hazards are caused by the breeding of flies, mosquitoes, rats and other pests.

(b) Obnoxious gaseous and particulate matter are produced by burning of the combustible solid wastes, resulting in air pollution.

(c) Open dumping requires large land areas which further aggravates the problem of land shortage for human habitation.

Sanitary Landfilling or Controlled Tipping:

Sanitary landfilling involves the disposal of municipal wastes on or in the upper layers of the earth’s mantle especially in degraded areas in need of restoration. In landfilling, the solid wastes are compacted and spread in thin layers, each layer being uniformly covered by a layer of soil.

The layer is covered by a final cover of about one meter of earth to prevent rodents from burrowing into the refuse and scattering. This is a biological method of waste treatment and bacterial refuse digestion results in decomposition products like CO9, CH4, NH3, H2S and H2O which can be harnessed as renewable sources of energy.

Advantages of Landfilling:

(i) Simple.

(ii) Economical.

(iii) Cheap equipment and plant is required.

(iv) Skill labour not required.

(v) Separation of different types of solid wastes is not required.

(vi) No residue or by product.

(vii) Low lying areas can be reclaimed and put to better use.

Disadvantages of Landfilling:

Large land area is required. Continuous evolution of foul smell at the site of disposal.

Use of insecticide is required. Covering of waste solid with good earth may sometimes difficult. It may also cause ground water pollution.

Pyrolysis or Destructive Distillation:

Pyrolysis is the process in which certain waste can be pyrolysed.

If it can yield valuable gases or liquids as by products, pyrolysis might be suitable.

In this disposal method, the solid wastes are heated under anaerobic conditions.

The organic components of the solid wastes split up into gaseous liquid and gaseous fractions (CO, CO2, CH4, tar, charred carbon).

Unlike the highly exothermic process of combustion, pyrolysis is a highly endothermic process and that is way it is also called destructive distillation.

Land-farming Soil Cultivation and Amendment:

In this waste disposal method, the biodegradable industrial wastes are treated by the biological, physical and chemical processes occurring on the surface of the soil.

The organic wastes are either applied on top of the land or injected below the soil surface with suitable equipment, where they undergo bacterial and chemical decomposition. At frequent intervals, the land farming sites can be reused without any adverse effect provided the land farming site is properly managed.

Compositing or Biodegradation:

Compositing includes waste like organic refuse such as kitchen waste, leaves, grass and handling these waste in such a way that naturally occurring bacteria and other micro- organism will break these down and produce safe, clean and soil like material called compost. It can occur in the presence of air or in a closed container or underground.

Receiving pits → send to hopper → Rotary vibrating screens→ Magnetic separator → Sorting belt/table → Mixing of sludge → Window pits → Rolls → Screen → Market preparation of fine intermediate and coarse humus.

Bacterial decomposition of the organic components of the municipal solid wastes result in formation of humus or compost and the process is known as compositing.

Compositing process — Waste preparation Digestion

Compositing — Compositing by trenching Open window compositing Mechanical compositing

Shredding:

Preparation of solid waste required reduction and uniformity in size for future use, for this a process is called shredding is devised, shredded waste can be utilized bestly for every use.

There are number of different types of size reduction machines which can be utilized bestly for every use.

There are number of different types of size reduction machines which can handle industrial wastes. They are rolling ring crushers, jar crushers, hammer mills, shredder and hags.

The rolling ring crushers and roll crushers use impact shearing and compression, and hammer mills use impact, attrition and shearing.

Hammer Mills:

This is most common type of industrial size reduction equipment. The hammer mill consists of large motor driven rotor to which are hinged a number of heavy hammers that pivot on this hinges and turn with the motor like so many blades of a saw.

The mill is enclosed with a hardened cover, and at one side of the mill is a hardened plate known as a breaker plate, and the material is ground to a smaller size by the impact of the hammer, the attrition between the particle and the breaker plate and the particle and other particles, and a shearing action caused by the hammer.

Each machine consists of several major components: the feed hopper, the main frame, the bearings, the rotor assembly, the breaker plates and the discharge grates. The machine should have protective devices and the adjustment features.

Hammer mills can have rigid or flexible hammers, light or heavy hammers according to the desirability of work. Breaker plate used to bear or absorbed crushing force and it is manufactured in a way to promote shearing action.

For Bulky Waste:

For some industries bulky waste is there required to be crushed or disposed. These machines consist of two multiple steel frames which are movable connected and where open are arranged in V-fashion. The bulky waste material is caught between two frames and cut up by cutting edges fixed at seven parallel steel sectioning pivoted rake sections are moved back and forth by two double acting cylinder (hydraulic).

In this process a compost pile is constructed by making alternate layers of organic matter and soil (source of micro-organisms). Some fertiliser and water is periodically added to the compost pile to stimulate microbial (bacteria and fungi) action and to maintain the necessary moisture content (55%).

(i) Index Method

(ii) Banting Method.

Biomethanisation Technology:

The organic portion is removed, this position goes into bio reaction which are closed with bacteria in it. The bacteria up the garbage and produce organic manure and biogas. Organic manure is used as inputs in chemical fertilizers and biogas can be used to produce electricity.

Disposal into Sea:

It can be done where deep sea water > 30 mm.

Reasonable distance ≤16 to 20 km. With strong forwards currents.

Advantages:

Simple, Cheap.

Disadvantages:

Bulky and lighter components float, spread and tend to return to the shore during high tide. During monsoon or stormy weather this is not possible. Some portion of the solid waste may return and spoil the beaches.