How to Control Water Pollution in Mining Industry:

Major sources of water pollution include:

(i) Mine water pumped out during drainage operations;

(ii) Spent water from handling plants, dust extraction and dust suppression systems;

(iii) Effluents from preparation and beneficiation plants;

(iv) Leachates/wash-offs from waste/tailing dumps.

Mine Water Pollution:

The mining Industry has to discharge millions of gallons of water every day to the adjacent water courses thereby may cause water pollution problems in and around the mining areas. Mine water discharge also forms the main source of various water supplies particularly potable in the thickly populated coal fields.

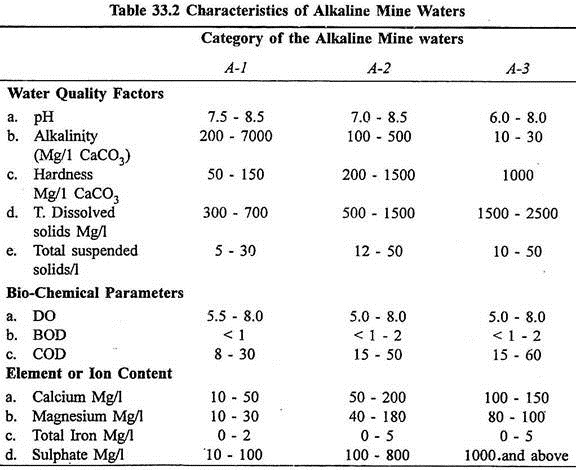

A classification of mine waters as arrived at on the basis of analysis of mine water from various coal mines of India is given in Table 33.1. General water quality characteristics of alkaline waters under each category are summed up in Tables 33.2.

Most of the alkaline mine waters fall under category A-2 which have High to medium concentrations of dissolved solids, suspended solids, hardness and sulphate with biochemical (BOD, COD) and toxic metals at insignificant concentration levels.

Category A-l, which is also slightly alkaline in nature, differ from those Category A-2 in that they are not hard and contain comparatively low concentrations of dissolved solids and sulphate. Chloride concentrations of both the categories are not very different and are generally lower than surplus concentrations. Mine waters of category A-3 contain very high concentrations of dissolved solids particularly chloride and their occurrence is rare.

There already exist Water Treatment Plants in various mining areas with the capacity of 25,000- 5,00,000 litre per day which are usually based on slow sand filtration; settling and filtration by coagulation using lime and alum followed by disinfection by chlorination etc.

Since the toxic metals and other substances are usually either absent or at insignificant concentration levels, the major chemical treatment is needed to remove and control suspended matter and bacteria.

A General Treatment Scheme:

Coagulants such as lime and alum, sodium-aluminate or polyelectrolytes are introduced into the inlet of a small mixing tank prior to entering the pyramidal flocculating settling tanks. Sludge produced in the settlement tank is drawn off frequently.

After Settlement the effluent is passed through enclosed pressure filters. Following pressure filtration, chlorine is added to the water in a small tank. Potable water thus results.

Acidic Mine Waters:

Acidic waters result in severe water pollution problems, Acid mine drainage (AMD) refers to the distinctive type of wastewater that originates from the weathering and leaching of sulphide minerals present in coal and metalliferrous ore bodies.

Effects of AMD water pollution include the fish kills and loss of other aquatic life; corrosion of mining equipment and structures such as barrages, bridges & concrete materials. Apart from the various metalliferous mines, AMD is most persistent pollution problem in north eastern (Assam) coal-mines. General water quality characteristics of acidic mine waters is given In Table 33.3.

Acidic waters to be used for industrial and other purposes or before discharging are usually treated by neutralisation. Alkaline material (lime/limestone) is mixed to neutralise the acid and precipitate the contaminating metal salts content.

The sludge formed by the sedimentation of the metal salts has a high water treatment and poses a difficult disposal problem. A process treating AMD using an active biochemical sludge followed by neutralisation is efficient and low in cost.

In this treatment scheme AMD waters are first equalised and then sent to activate sludge process. When drainages are pretreated in bio-chemical oxidation chamber with iron-oxidising bacterial cultures, ferrous salts are readily converted to ferric and then finally precipitated.

Limestone is used for neutralising AMD and then passed to sedimentation tank. The sludge is usually filtered either in a vacuum filter or dried on sludge drying beds before the cake is wasted. The treated AMD can be used for various industrial or afforestation purpose.

At source control of AMD by the application of certain environmentally acceptable compounds such as anionic surfactants, food Preservatives etc. which retards/controls pyrite oxidation by inhibition of bacterial activity controls over 70% of the acidity produced. The overall control can be effected with the supplementation of water treatment scheme as described above.

How to Control Air Pollution in Mining Industry:

Particulates, SO2 NOx, CO and hydrocarbon emissions are considered major air pollutants in mining areas. Out of these, particulates are a major hazard and mining authorities are giving utmost attention in controlling these by various suppressive and preventive measures.

The particulates may be released into atmosphere from point sources such as chimney, a centralised vent system to exhaust dust laden air from crushing and screening plants.

The important non-point sources of particulates and other gaseous pollutants are:

(i) Operation of various coal/mineral mining and overburden removing equipment such as shovel, front and loaders, draglines, bucket wheel excavators, bulldozers, drilling rigs etc.

(ii) Haul roads both of the paved and unpaved types, wind erosion from coal/mineral stockpiles, benches and overburden dumps;

(iii) Blasting operations;

(iv) Tailing Dumps;

(v) Transportation activities on poorly maintained roads; and

(vi) Coal burning activities.

Ambient air quality status with respect to suspended particulate matter (SPM), SO2 and NOx over one year period each season-wise for some coal mining areas of Raniganj and Jharia coalfields as monitored during 1989-1990.

Prevention and Control of Air Pollution:

Following measures are, in general in practice for prevention and control of air pollution in mining industry:

(i) Dust suppression through heavy duty sprinklers/road watering tracks is being done at various sensitive points such as haul roads, coal/ore handling points, crushing and screening plants etc.;

(ii) Dust extraction facilities are provided with various heavy mining equipment crushing and screening plants; and coal/ore handling Plants, water sprays, hoods, dust collectors are used to control dusts from drilling;

(iii) Measures such as adoption of hoods at transfer points, proper design of chutes, vulcanising of conveyor belt joint under belt cleaning devices apart from dust suppression and/or dust extraction systems for conveyors are introduced to minimise dust pollution;

(iv) Coal/ore handing plants are being covered with proper enclosures;

(v) Transportation (trucks/dumpers and railway wagons) are being properly covered and leak proof. Suitable chemicals are also being sprayed on the top to prevent dusts from being airborne;

(vi) Sprays containing small amounts of calcium chloride or aluminium hydroxides are being provided which effectively results in airborne dust settling. The same is also being applied to unpaved roads, haul roads;

(vii) Stabilisation through vegetation at various critical points and green belts are being provided along the road sides, in colony and around project areas. However, suitable design with certain selected species which positively respond to adsorption/absorption of dusts/gaseous pollutants, must be considered before going for the creation of green belts.

Land Damage:

Degradation of land is the most significant impact of mining. In India, about 0.75% of the total land surface of 304 million hectares is under mining lease. 175 million hectares of land has been degraded to various degrees.

Mining activities are to involve 1200 hectares of forest area per year at production level of 400 million tonnes of minerals and the forest area of the country has been reduced from 23% of the entire land to 10.63%.

The total number of working mines reported in 1982 was 5510. Out of that 516 are coal mines and the remaining 4994 in the non-coal sector. The visual impact of mining on land is the aesthetic damage due to disfiguring of landscape.

Opencast/Surface Mining Impacts:

Overburden movement to external dumps conflicts with land- use for agriculture/forestry yields huge voids left after excavation; rapid erosion of land, slope stability problems; destruction of soil and vegetation; silting and degradation of streams and water bodies caused by erosion of soil; geomorphological changes and consequent changes in drainage pattern; and drainage of water from aquifers in surrounding areas resulting in depletion or drying up of wells/springs/streams and also drying up of swamps/pastures.

Underground Mining Impacts:

Subsidence of land results in ecological changes as well as endangers nearby structures, buildings, etc. Mine fires result the land sterile with other consequent adverse impacts.

Land Reclamation:

Reclamation is the process to put the land to some productive use.

The entire reclamation procedure can be divided into two parts:

1. Technical Reclamation and

2. Biological Reclamation.

1. Technical Reclamation:

It refers to backfilling of the excavated area with overburden and spreading of subsoil and topsoil with grading at each stage.

Reclamation methods can be broadly classified into the following categories –

(a) Shovel dumper combination;

(b) Bucket wheel excavator

(c) Stripping shovel or dragline;

(d) A system using dragline and shovel dumper and

(e) In-pit crusher and hybrid transport system.

Though reclamation method may vary slightly depending upon the type of equipment used for excavation of overburden and coal/ore, the basic method remains the same in all these cases.

In reclamation process, creation of the most favourable seed bed necessitates some earth work in the form of regrading and ripping. This earthwork facilities burial of toxic materials (or prevents their unearthing) and selection of the most favourable substrate to growth for final spreading.

Regrading of sloped may be required to remove steep slopes, bury toxic wastes, simplify seed-bed preparation, lessen problems of soil temperature and stability due to erosion, extend tip area to surrounding areas from which top soil can be stripped for re-spreading, backfill the pit or quarry partially or completely.

Regradation is site-specific. Final contours are determined by the relative requirements of the land use, cost of earth moving and availability of space to spread the waste, apart from the needs of revegetation.

Generally, gradients of 1 in 4 to 1 in 10 for trees; 1 in 10 for grazing lands; 1 in 20 for arable lands and not flatter than 1 in 25-30 for drainage are required. It is very difficult to avoid compaction during earthwork, therefore, after the final contours have been established, ripping may be required with one or more of the following objectives –

(i) To break up compaction and permit root penetration;

(ii) To assist in water infiltration and thus lessen run off;

(iii) To bring to surface, the large stones to be picked or broken;

(iv) To enable better keying of soil layer to the waste surface;

(v) To establish hydraulic continuity between layers.

It is important that ripping is carried out along contours and not down the dip. Surface stabilisation of bare land particularly when the waste are fine, conditions are arid and wind erosion is likely, can be done by physical and chemical means. Physical stabilisation is achieved by re-spreading topsoil, water spraying and mulching.

Chemical stabilisation can be done by reacting of an appropriate reagent to stabilisation from an erosion resistant crust. Soil erosion control from slopes is done by providing terracing and benching of OB slopes, stabilising by suitable species of grass, shrubs, bamboo barricading etc. However, vegetation is the only method of achieving long term stability.

Soil conservation efforts at North Eastern Coalfields as listed below are noteworthy:

(i) Provision of garland drains and diversion of existing ones away from OB dumps to prevent soil wash out;

(ii) Check dams around backfilled OB dumps;

(iii) Bamboo barricades in gullies and also staggered across OB dumps to prevent erosion of loose OB by flow of water channels along the dump sides;

(iv) Terracing/benching of OB slopes, broadcasting of suitable species of grass and shrubs and creepers for soil binding as well plantation of species suitable for hostile soils, have been provided on the terraces;

(v) Erection of stone walls at the toe of OB dumps to contain flair of silt ad their effectiveness to ascertain the ‘fill up’ in them;

(vi) Another costly measure being adopted, is the erection of dams across stream to prevent silting and to serve as catchment areas; and

(vii) A continuous length of bamboo barricade with Hessian cloth lining on the inside, is being provided around all the coal dumps to prevent flow of even the smallest coal particles into streams and water courses.

2. Biological Reclamation:

This is the most difficult phase of the reclamation process as the establishment of plant growth on the reclaimed soil which hacks in nutrients, organic matter, ‘microbial activity’ etc.

Soil analysis, fertiliser application, mulching and seeding or planting of plant species etc. comes under biological reclamation. Spoils can be covered with various organic mulches such as straw, hay, crop residue, tree bark, saw mill waste, refuse end other composed organic residues to increase vegetation cover and reduce the sedimentation losses.

Mulching can help in plant growth by preventing erosion both by water and wind; facilitating infiltration, providing and protecting seedlings; re-inoculating micro-organism into mined soils and possibly adding desired seeds while acting as a mulch.

Vegetation need not be done by going in for monoculture or for large scale introduction of exotics, the restoration efforts should be planned to create a mosaic of species, having atleast some of the characteristics of the original flora.

Achievement of a self-sustaining vegetation cover can be approached through natural plant succession utilising pioneer species able to exist under harsh soil conditions. These may improve the site through their rooting and incorporation of organic matter gradually changing the soil In order that species of secondary succession can be grown.

The process of revegetation can he substantially speeded up by seeding with grasses, herbaceous legumes as first stage colonisers which provide soil building for pioneer invaders in different stages of succession.

Revegetation through natural plant succession has successfully been demonstrated at various mined out/mine spoil sites of Amarkantak Bauxite Project, North Eastern Coalfields (Assam).

Reclamation of mined out lands is a recent development in India. A lot of land damaged by mining is still abandoned. However, many successful attempts have been made for reclamation of mined out areas during last two decades.

Of the various mining organisations where good and sincere efforts have been made in this direction the exemplary and noteworthy are – Neyveli Lignite Corporation, North Eastern Coalfields, Dhanpuri Opencast Project of SECL, Jogta Fire Project of Jharia Coalfields, Umrer Opencast Project of Western Coalfields Ltd, Rajrappa Project of Central Coalfields Ltd, Gidi-A & Gidi-C of West Bokaro Opencast Projects of TISCO, Singrauli Coalfields, Amarkantak Bauxite Mine of BALCO, Kudremukh Iron Ore Co. Projects, Kolar Gold Fields, Tirooli Mine of MOIL, Stone Quarries of Iron Works, Timba Road, Gujarat, many mining areas in Mussoorie Hills, Charkhi Dadri Kankar Mine (Haryana) of CCI and many projects elsewhere.